Service process

01. Design

Our skilled engineers will determine the customer's exact needs and adjust the customer's design plan to create a product packaging design solution that accurately meets the customer's needs. Our engineers' mission is to design good products while minimizing costs.

02. Mold making

For blister packaging products, we need to make plaster molds, and then make copper molds or aluminum molds, so that we can use vacuum forming machines for mass production.

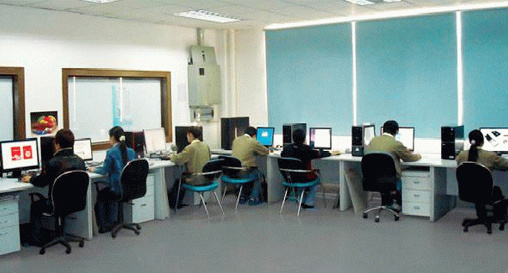

03. Type Setting

For plastic or paper packaging boxes, after the layout design, we set the type through the computer, and then enter the CTP (Computer to Plate) program.

04. Mass production

For blister packaging products, we need to make plaster molds, and then make copper molds or aluminum molds, so that we can use vacuum forming machines for mass production.

05. Quality inspection

In strict accordance with the process of quality testing, has passed the ISO9001,ISO14001,SA8000 certification, QS license.

06. Filler

07. Warehousing

08. Transportation